AMS delivers worlds first recycled metallic materials onto future aircraft system.

Additive Manufacturing Solutions Ltd. (AMS) is proud to announce its collaboration with the UK Ministry of Defence (MOD) and Rolls-Royce in a groundbreaking initiative to recycle components from retired Tornado aircraft into new parts for the next-generation Tempest fighter jets. This innovative project marks a first for the UK, showcasing the potential of recycling and additive manufacturing techniques in defence applications. This project was titled Tornado 2 Tempest. This project delivered a world first of its kind recycled metallic part onto an aircraft, recycled metals have never made it onto an aircraft test or production.

This is the sort of project that comes around very rarely, being able to work on a project that is aligned with our own visions of using advanced manufacturing technologies whilst trying to help the UK become a more environmentally sustainable outfit in all areas. The first part of the project was to show that AMS could use end of life parts from a Tornado aircraft and create a new part for the next generation of aircraft, the Tempest.

AMS is honoured to contribute its expertise in additive manufacturing to this collaborative effort, reinforcing its commitment to advancing environmentally sustainable and efficient solutions within the aerospace and defence sectors. Robert Higham, AMS Co-founder and CEO stated: “This project turned our proposed solutions into a reality, and we have been very humbled and grateful to the MOD and Rolls Royce, for allowing us to showcase our capability to deliver game-changing circular economy processes and parts in Defence.”

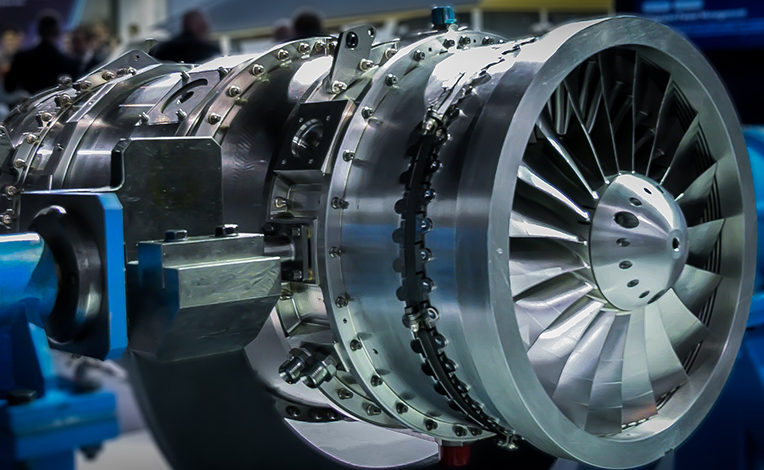

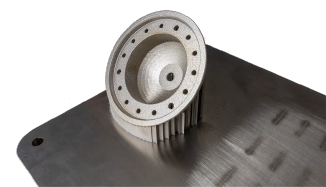

The process involves dismantling surplus Tornado aircraft to extract high-criticality metals such as titanium. These materials are then atomised into powders, which serve as feedstock for 3D printing new components. AMS successfully utilised this method to produce a 3D-printed nose cone for Rolls-Royce’s Orpheus engine, a key element of the MOD’s Future Combat Air System (FCAS) program delivering Tempest. The newly manufactured nose cone was fitted onto an Orpheus test engine and passed rigorous suitability and safety checks, demonstrating the viability of this recycling approach for future military aircraft.

Source:

AMS have also been awarded the Chief of Defence Logistics and Support (CDLS) Commendation for this project due to our commitment and dedication to the delivery and improvement of support to the front line, alongside the other members of this successful project.

For the full list, please see this:

https://www.gov.uk/government/news/defence-support-cdls-commendations-2024.